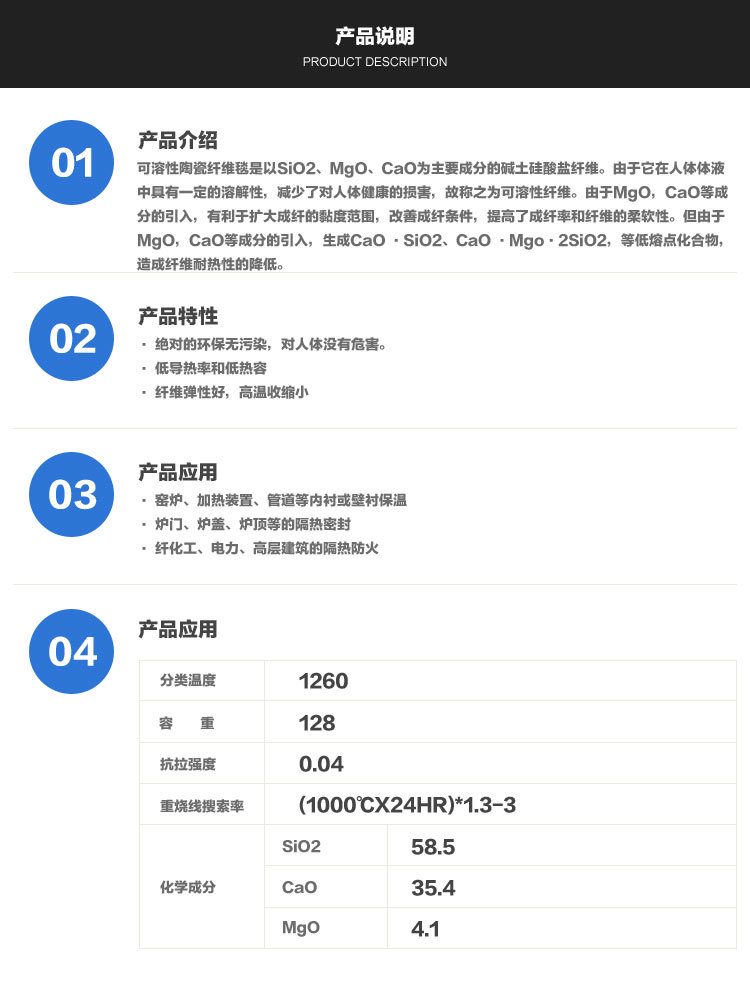

由于MgO,CaO等成分的引入,有利于擴(kuò)大成纖的黏度范圍,改善成纖條件,提高了成纖率和纖維的柔軟性。但由于MgO,CaO等成分的引入,生成CaO ·SiO2、CaO ·Mgo·2SiO2,等低熔點化合物,造成纖維耐熱性的降低。故一般可溶性纖維屬于低檔陶瓷纖維,其產(chǎn)品多用作工業(yè)窯爐背襯材料。為提高可溶性纖維的耐熱性能,采用了引人zrO2成分的方法,以提高玻璃相黏度,抑制纖維受熱結(jié)晶后晶粒生長速率,實現(xiàn)可溶性纖維耐熱性能的提高。目前美國、英國、法國等國家都相繼開發(fā)了此種產(chǎn)品,并作為商品投放市場。

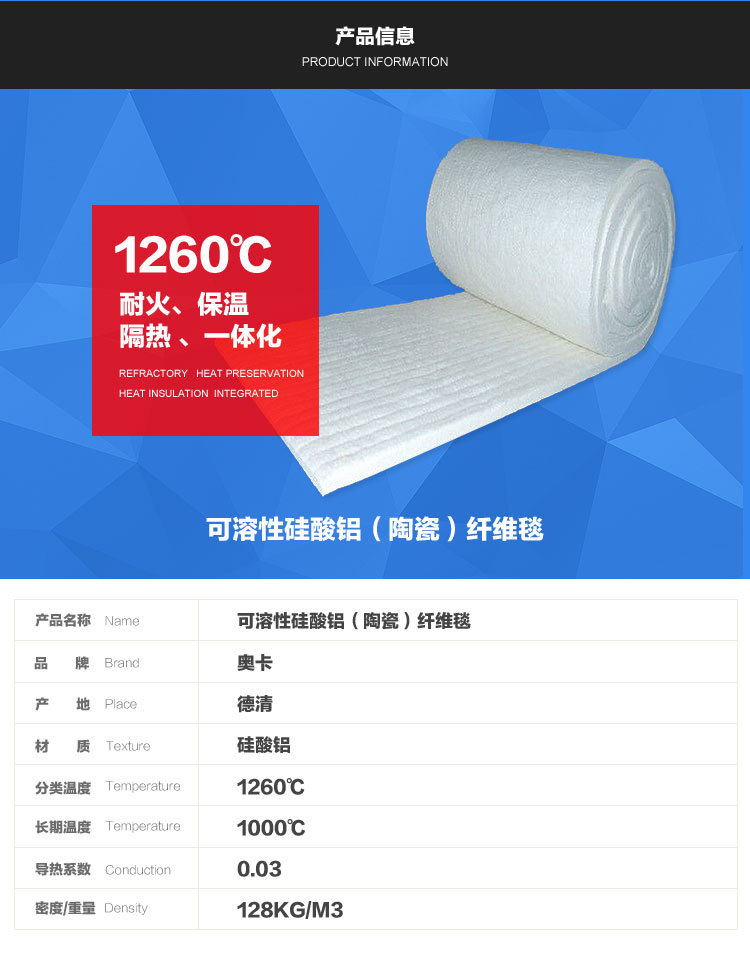

可溶性纖維的品種有散狀纖維、針刺毯、濕法真空成型制品等